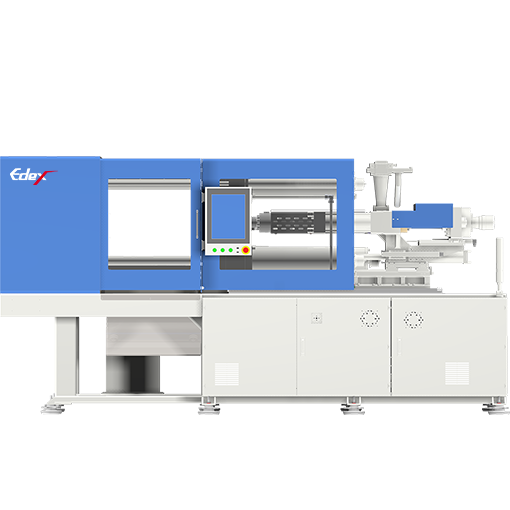

Horizontal Type

ATOR Series features

- Variable mold center distance rotary injection molding machine

- The narrowest injection seat design allows central distance adjustment fo two injection seats according to requirement.

- The independent rotary table can accommodate all molds as long as their central distances fall within the application scope.

- The rotary table with hidden hot and cold water paths allows neat configuration of mold water channels.

- The fixed mold platen module with movable central distance allows interchanging of different center distances.

- Full modular machine design with interchangeable plunger type and screw type injection unit.

Specifications of ATOR Horizontal Rotary Dual-color resin Plunger Type (Screw Type) Injectin Molding Machine

Screw Type

Plunger Type

.jpg)

ATOR600-IS70 / SP70

-

Clamping force : 600 kN

- Max mold dimension : 150 x 300 / 200 x 400 mm

- Rotary table dimension : 550 mm

- IS70+IS70

- Screw diameter : 18 / 22 / 25 mm

- Injection volume : 25 ~ 49 cm³

- SP70+SP70

- Screw diameter : 18 / 22 mm

- Plunger diameter : 12 / 16 / 20 mm

- Injection volume : 13.5 ~ 37.6 cm³

-

Add to inquiry

ATOR1200-IS170 / SP100

-

Clamping force : 1200 kN

- Max mold dimension : 200 x 400 / 300 x 600 mm

- Rotary table dimension : 700 mm

- IS170+IS170

- Screw diameter : 22 / 25 / 28 mm

- Injection volume : 56 ~ 92 cm³

- SP100+SP100

- Screw diameter : 22 / 26 mm

- Plunger diameter : 16 / 20 / 24 mm

- Injection volume : 24.1 ~ 54.2 cm³

-

Add to inquiry

ATOR2000-IS250 / SP300

-

Clamping force : 2000 kN

- Max mold dimension : 300 x 600 / 420 x 840 mm

- Rotary table dimension : 980 mm

- IS250+IS250

- Screw diameter : 25 / 28 / 34 mm

- Injection volume : 83 ~ 138 cm³

- SP300+SP300

- Screw diameter : 35 mm

- Plunger diameter : 22 / 28 / 34 mm

- Injection volume : 68 ~ 163 cm³

-

Add to inquiry

TOP

.jpg)