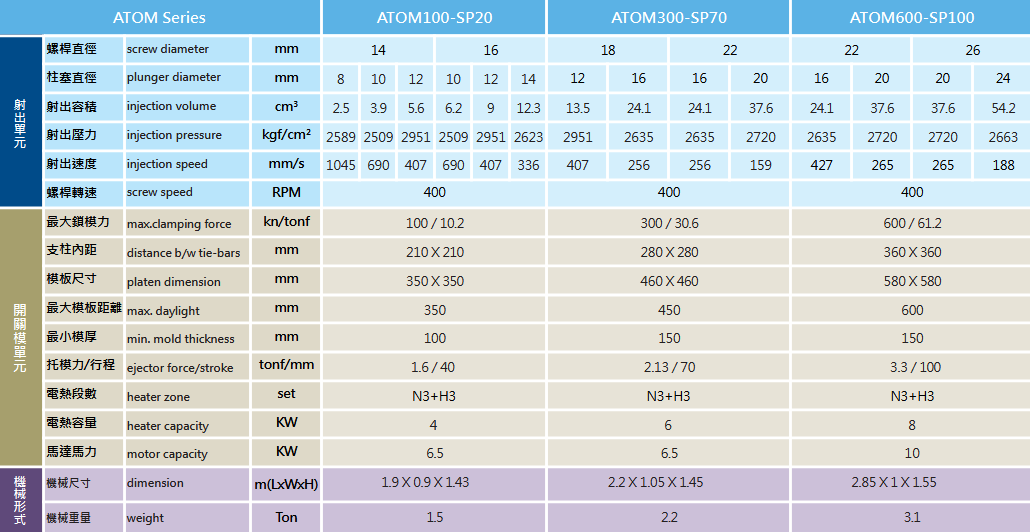

- Clamping force : 100 kN

- Distance between tie-bar : 210 x 210 mm

- Screw diameter : 14 / 16 mm

- Plunger diameter : 8 / 10 / 12 / 14 mm

- Injection volume : 2.5 ~ 12.3 cm³

- PRODUCTS

- Micro injection machine

- Atom Series

Plunger injection is the most precise injection molding method in the world

Resin is homogeneous and well melted and the simplified screw structure design to make screw life longer. Plunger type prevents backflow risk and own the most precise shot-end position, it’s easy to complete precise injection. Interchangeable Plunger Injection System (IPIS) adapts to different requirements of injection performance by changing injection units to meet full-functional (All-in-one). The final choice of injection machine extends injection machine life and saves money from replacing machines.

The greatest performance in precise injection

- The most precise shot-end position, high repeatability.

- The highest injection penetration produces high-end products.

Revolutionary new plunger injection method enhances the efficiency of production greatly

- Perfect mix of melted resin, stable resin density, can significantly shorten the cycle time up to four times the capacity.

Specifications of VTOP Series

Atom100-SP20

Atom300-SP70

- Clamping force : 300 kN

- Distance between tie-bar : 280 x 280 mm

- Screw diameter : 18 / 22 mm

- Plunger diameter : 12 / 16 / 20 mm

- Injection volume : 13.5 ~ 37.6 cm³

Atom600-SP100

- Clamping force : 600 kN

- Distance between tie-bar : 360 x 360 mm

- Screw diameter : 22 / 26 mm

- Plunger diameter : 16 / 20 / 24 mm

- Injection volume : 24.1 ~ 54.2 cm³

Samples