What is Clamping force? And how its related to injection molding?

Clamping force is an important function in the injection molding process. In the injection molding process, the clamping force is a main parameter that determines the quality of the output product. Appropriate clamping force setting can make the production more stable and improve the quality. Improper setting of clamping force will result in unstable production and loss of mold.

What is clamping force?

Clamping force, is the force for locking the mold. In the injection molding process, the injection unit needs to create a certain force to push the melted plastic, when the plastic is injected into the mold cavity, the injected area of the product in the mold cavity generates a corresponding force to the mold. In order to avoid this situation, it is necessary to clamp the mold with a corresponding clamping force to avoid burrs and other undesirable situations in the product.

Clamping unit types

Toggle type

The principle of toggle type clamping is to use the multi-joint structure to straighten the tie-bars when closing the mold to create the clamping force. The driving force can be amplified by 20 to 23 times through the toggle structure. The advantage is using a lower drive power source to produce the required clamping force, and the cost is cheap. The disadvantage is that the clamping force distribution is relatively uneven, and the toggle structure is complex, requiring long-term lubrication and the toggle structure is not easy to maintain after wear.

Direct clamping type

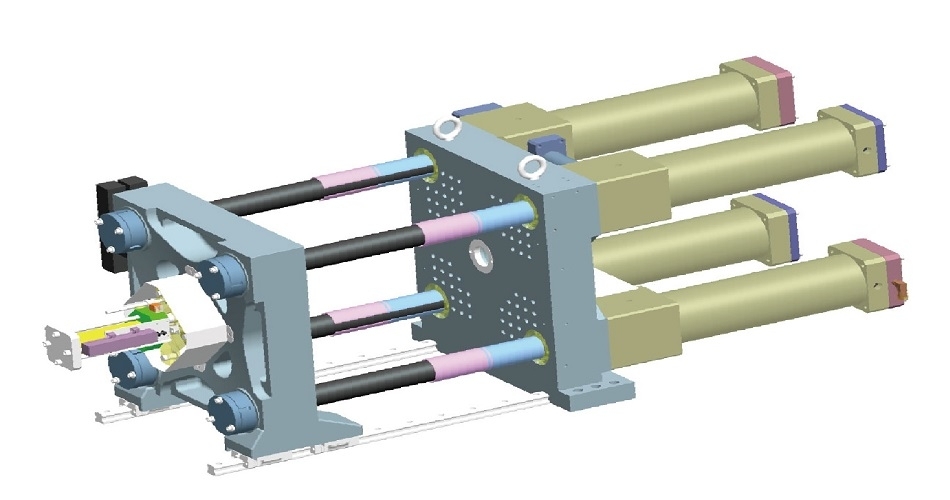

The direct clamping structure uses the hydraulic cylinder to directly generate the clamping force for the movable mold platen. It does not require structural enlargement, and directly exerts force on the mold plate. The user can directly set the required clamping force, and the clamping force adjustment is easy. The direct clamping structure has an even distribution of the clamping force, which can improve the lifetime of the mold and the quality of the product. The follow-up maintenance cost is lower than toggle type. The common direct clamping mechanism is a single-cylinder direct clamping mechanism and a four-cylinder direct clamping mechanism.

Toggle type vs Direct clamping type

| type | Toggle type | Direct clamping type |

|---|---|---|

| Features | Use the multi-joint structure to straighten the tie-bars when closing the mold to create the clamping force |

Use the hydraulic cylinder to directly generate the clamping force |

| Advantage | Low cost | Even distribution of the clamping force Higher mold lifetime Lower maintenance cost Mold adjustment free |

| Disadvantage | Requiring long-term lubrication Structure wear |

Higher cost |

What is the effect of clamping force on injection molding?

In general production, it is not recommended that the clamping force is too high or too low. If the clamping force is too low, it is easy to cause the product to be stretched, burrs and size NG, which will affect the quality of the product. If the clamping force is too high, it will reduce mold life and equipment life, also increasing mold and equipment maintenance costs. Excessive clamping force will also lead to poor exhaust in the cavity and reduce yield.

Factors causing insufficient clamping force

1. Poor clamping settings.

2. The actual clamping force requirement of the mold is greater than the injection machine specification.

3. High injection pressure setting.

4. Injection machine needs maintenance.

Methods to improve insufficient clamping force

There are many reasons can lead to insufficient clamping force. In addition to equipment factors, if the clamping force is insufficient, check the mold design to avoid the need for excessive clamping force during production due to mold flow factors. At the same time, adjust the parameters of injection, the maximum clamping force used in production is about 80% of the equipment. If the required clamping force is close to the equipment specifications, it is recommended to use equipment with higher clamping force.

The most precise, durable 4 cylinder direct clamping system - EDEX

〈Extended reading: 2-Platen 4-Cylinder Direct Clamping System〉

Conclusion

Clamping force is a very important standard when selecting equipment. Appropriate clamping force specifications can make production smoother. In addition to clamping force specifications, the structure of the clamping unit also needs to be understood. The EDEX’s 4 cylinder direct clamping system is superior to the traditional clamping structure in terms of precision, durability, and average clamping force. The precise 4 cylinder direct clamping system allows customers to improve the yield and quality during production, and has the shortest machine length of the same specification. It can greatly improve the utilization rate of the plant. If you need further information, please contact our company for further consultation.

最近的文章

- What are the ways of silicone molding?

- Plastic injection knowledge: 5 common undesirable phenomena and solutions

- What are the causes of injection molding defects?

- What are injection molding machines ? What are the types?

- What are low pressure injection machines? The 4 advantages of low pressure injection must be understood!